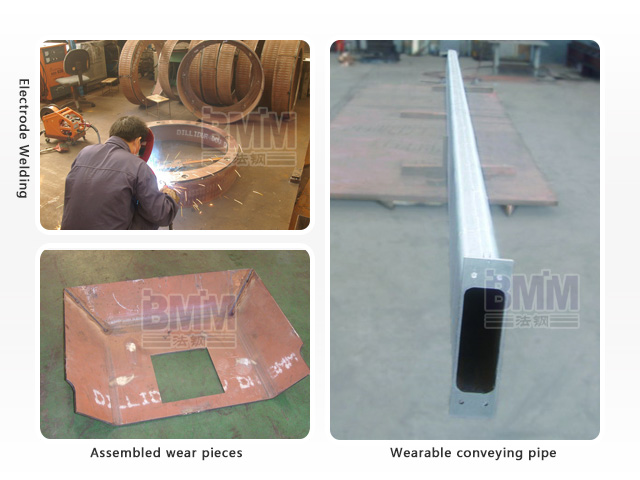

Thanks to the low carbon and low alloy contents, the wear resistant plates can offer you a prefect balance between the high wear resistance and good weldability . As long as the general rules of welding technology are observed, wear resistant plates are very suitable for welding with normal welding techniques. By using high-quality wear-resistant plates and strict process management, BMM can provide various types of wear-resistant welded structure.

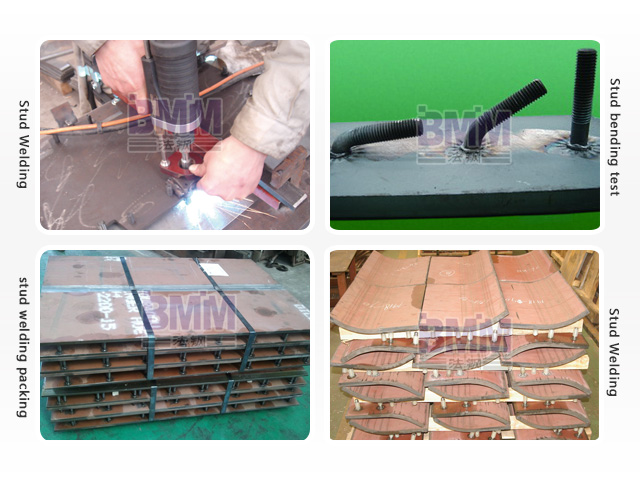

stud welding

The stud welding process is a rapid, convenient, reliable and economical choice for stud connection & installation. Compare with countersunk, drilling & tapping process, use of stud welding process on the WR plates is more efficient but low-cost. The stud welding process is also simple but better perform compare to the traditional welding process. Furthermore, more protection on the wear parts will help to reduce the design toralance and can effectively extend the service life on the wear parts.

The stud welding process is a rapid, convenient, reliable and economical choice for stud connection & installation. Compare with countersunk, drilling & tapping process, use of stud welding process on the WR plates is more efficient but low-cost. The stud welding process is also simple but better perform compare to the traditional welding process. Furthermore, more protection on the wear parts will help to reduce the design toralance and can effectively extend the service life on the wear parts.

By fully use its direct resources advantage, advanced stud welding machine & welding technology, BMM is always ready to be the optimal “Wear Solution Provider” with the best quality steel liner plates.